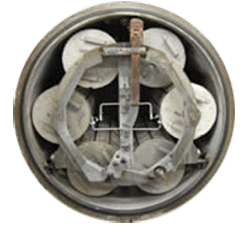

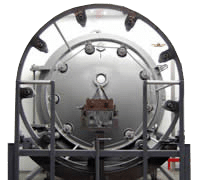

For over 60 years, our customers have relied on us to meet their vacuum metalizing and PVD sputtering needs. Vacuum metalizing is the process of evaporating metals, most commonly aluminum, inside a vacuum chamber where it bonds to the desired substrate to achieve a uniform metalized layer.

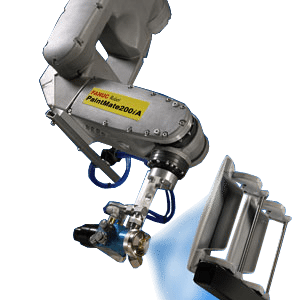

Thermal evaporation, otherwise known as vacuum metalizing, is the most common PVD (Physical Vapor Deposition) process. Sputtering is the process whereby atoms are ejected from a target (e.g. chrome, stainless steel, copper, etc.) and are deposited on the substrate to form a thin, metalized coating.

Vacuum Metalizing has many functional and decorative applications, including but not limited to:

- EMI/RFI shielding

- Decorative chrome and metallic finishes

- Highly reflective coatings

- Heat shielding

- Vapor barriers